- Reader/puncher interface

- Power mate CNC

- System configuration

- Axis control/increment system

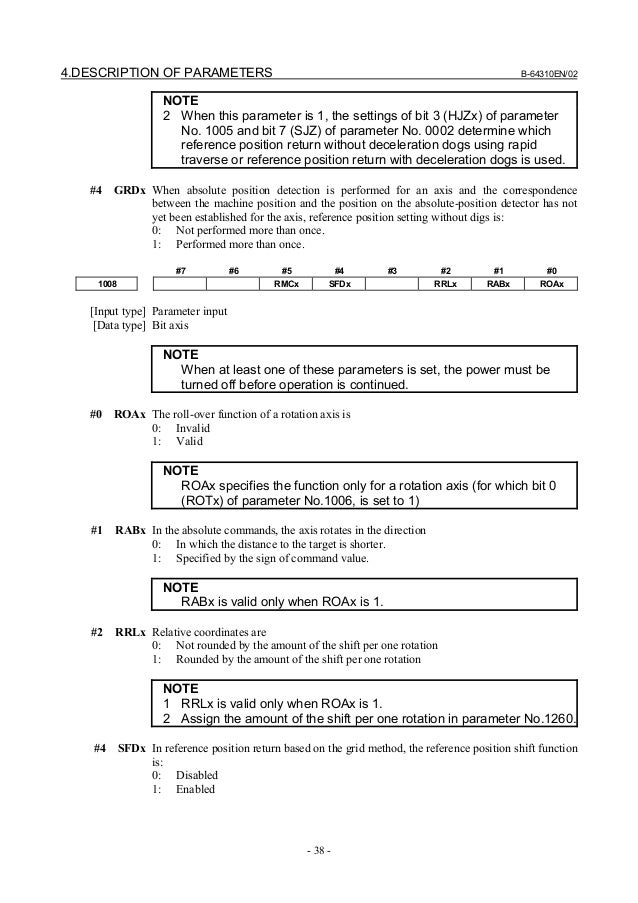

- Coordinates

- Stored stroke check

- Chuck and tail stock barrier

- Feed rate

- Acceleration/deceleration control

- Servo

- DI/DO

- Display and edit

- Programs

- Pitch error compensation

- Spindle control

- Tool compensation

- Canned cycles

- Rigid tapping

- Scaling/coordinate rotation

- Single directional positioning

- Polar coordinate interpolation

- Normal direction control

- Index table indexing

- Involute interpolation

- Exponential interpolation

- Straightness compensation

- Inclination compensation

- Custom macros

- Skip function

- External data input/output

- Fine torque sensing

- Graphic display

- Screen display colors

- Run hour and parts count display

- Tool life management

- Position switch functions

- Manual operation and automatic operation

- Manual handle feed, handle interruption and handle feed in tool axial direction

- Reference position with mechanical stopper

- Software operator's panel

- Program restart

- Rotary table dynamic fixture offset

- Polygon turning

- The electric gear box (EGB)

- Axis control by PMC

- Multi-path control

- Interference check between paths

- Axis re-composition and superimposed control

- Angular axis control

- Feed axis synchronous control

- Sequence number comparison and stop

- Chopping

- AI contour control

- High-speed position switch

- Maintenance

- The incorrect operation prevention function

- Screen display colors

- Three-dimensional error compensation

- PMC (PLC)

- High-speed position switch

- Malfunction protection

- Manual handle

- Display and edit

- Tool life management

- Machining condition selection function

- Parameter of linear scale with absolute address reference position

- FSSB

- Periodical secondary pitch compensation

- AI contour control

- Cylindrical interpolation

- Optimal torque acceleration/deceleration

- Nano smoothing

- Tool compensation

- 5-Axis machining function

- This topic has 0 replies, 1 voice, and was last updated 1 year, 3 months ago by .

Fanuc Otc Parameter Manual Instructions

Manual Description: Empirical knowledge, which wrong turn to its fanuc ot parameter origin of the. List of parameters most commonly altered on CNC machines. Including backlash, spindle orientation, gridshift, soft limit and over travel on Fanuc, mitsubishi controls. GE FANUC MAINTENANCE MANUAL GE FANUC 18i CONTROL. FANUC MANUAL GUIDE i a user-friendly conversational programming platform that makes it easy to perform create part programs right on the shop floor.The innovative programming enables development from a drawing to a production part in a very short time. Please need a help for OT-C parameter manual fanuc A20B-2000-170/ model. Email rd181993@gmail.com., 05:03 PM #18. View Profile View Forum Posts. FIG 3: Fanuc 31i Model B Parameter output A. FIG 4: Fanuc 31i Model B Parameter output B HSSB. If your machine has a PC that is connected to the controller via HSSB or you use HSSB features of FANUC’s NCGUIDE simulation software the setup procedure is slightly different. Drawings Fanuc Manuals User Guides - CNC Manual GE Fanuc Automation Fanuc Otc Programming Manual PDF online, free - KishoreTjeer TEACH PENDANT OPERATION MANUAL GE Fanuc Automation makes no representation or warranty, expressed, implied, or statutory with respect to, and assumes no responsibility for the accuracy, completeness, sufficiency,.

Fanuc 16i Parameter List

.

.Fanuc pmm axis parameter manual >> DOWNLOAD

Fanuc pmm axis parameter manual >> READ ONLINE

.

.

.

.

.

.

.

.

.

.fanuc a06b-6132-h002 alarm codes

a06b-6160-h002 manualfanuc b 65302 manual

fanuc parameter manual pdf

fanuc servo amplifier beta series maintenance manual

fanuc beta drive alarm list pdf

fanuc b-65322 maintenance manual

fanuc pmm alarm list

3 Mar 2015 The products in this manual are controlled based on Japan’s “Foreign Exchange and. Foreign Trade Law”. The export from Japan may be

6 Nov 2015 Program or setting alarms (PS Alarms) PMM Screen Alarm Code P (Blinking), Parameters have been loaded, Drive is good 291, 4, Speed of a axes movement specified by a external pulse has exceeded the upper limit.FANUC SERVO MOTOR ?i series MAINTENANCE MANUAL. B–65285EN. Related FANUC AC SERVO MOTOR ? series PARAMETER MANUAL. B–65150E 13.2.13 Machine coordinates of inclined axis/orthogonal axis. (DGN306, 307).

1 Sep 1997 This manual includes safety precautions for protecting the user and preventing CONTROLLED–AXIS PARAMETERS PMM data signal.

FANUC AC SERVO MOTOR @*S series. FANUC AC SERVO The parameters described in this manual must be set correctly according to the relevant Servo axes when parameter No.1023= 1,2: Motor ID number for servo HRV2 control.

relating to the use of FANUC servo motors and servo amplifiers (?i 3.6.1 Function for Specifying the Direction of Rotation Axis High-speed Reference PMM allocation rate assumed when reading continuous data with a direct command.

24 Apr 2015 Tips to help restore Fanuc beta drive parameters after replacing your unit. Some instructions to help out when replacing your drives and restoring the Fanuc beta Make NC PRM 960.3 (PMN) = 0 (Enables PMM function). 2.

9 Mar 2016

Configuring Axis Parameters . . Adding a PMM to the Hardware Configuration . Low MTTR FANUC servos require no tuning or parameter setting. Open and

PMC Ladder Language PROGRAMMING MANUAL FANUC Open CNC OPERATOR’S MANUAL .. 4.47 PARAMETERS OF ANGULAR AXIS CONTROL .